-

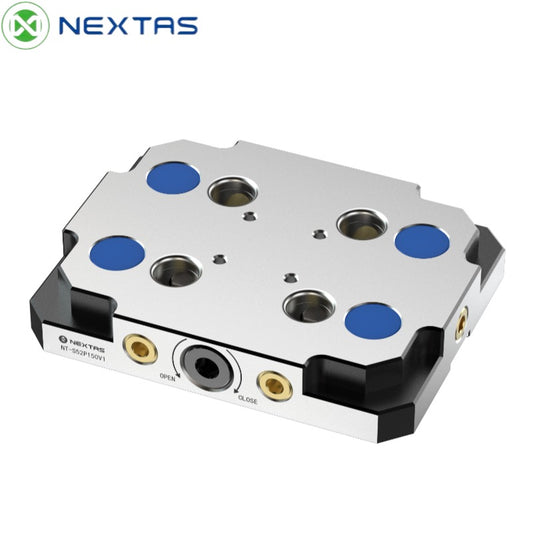

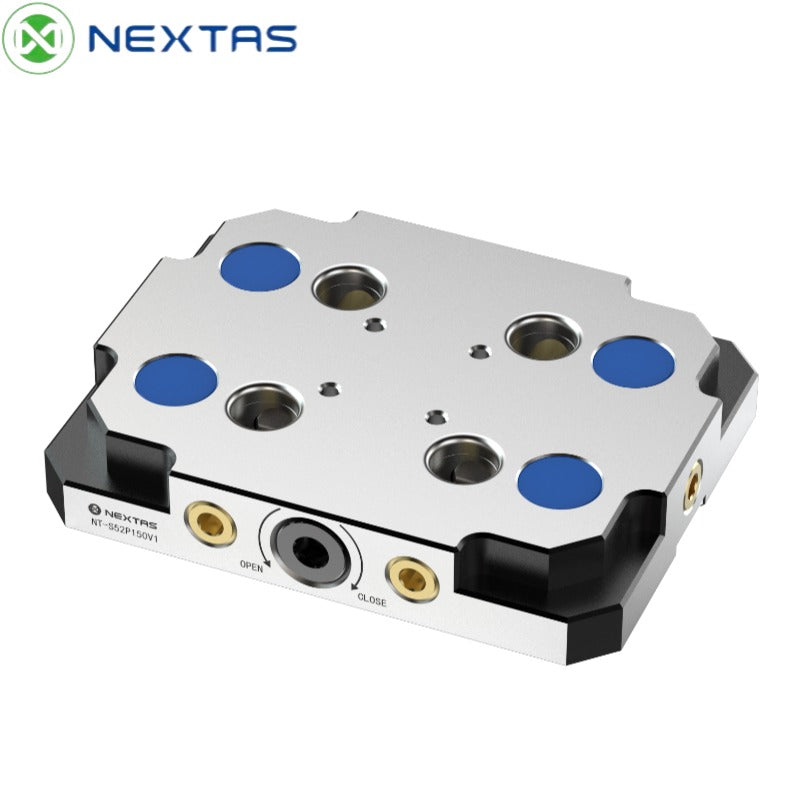

Nextas 52mm Zero Point Plate - 150 x 116 x 27mm

Regular price £395.00 ex VATSale price £395.00 Regular priceUnit price perThe Nextas Zero Point Plates deliver a fast, rigid and repeatable method of securing fixtures, vices and tooling in a CNC machining centre. A single locking...

-

Nextas 96mm Zero Point Plate - 192 x 156 x 27mm

Regular price £445.00 ex VATSale price £445.00 Regular priceUnit price perThe Nextas Zero Point Plates deliver a fast, rigid and repeatable method of securing fixtures, vices and tooling in a CNC machining centre. A single locking...

-

Nextas 52mm Zero Point Pull Stud - 4pcs

Regular price £30.00 ex VATSale price £30.00 Regular priceUnit price per52mm clamping studs serve as the interface between the zero-point clamping system and the clamping device. They can be fitted to vices, risers, custom fixtures, and...

-

Nextas 96mm Zero Point Pull Stud - 4pcs

Regular price £36.00 ex VATSale price £36.00 Regular priceUnit price per96mm clamping studs serve as the interface between the zero-point clamping system and the clamping device. They can be fitted to vices, risers, custom fixtures, and...

52/96mm Zero Point Workholding

Nextas Zero Point Plates provide a rigid and repeatable way of mounting vices, jigs and fixtures in a machine tool. The modular quick change design reduces setup time and minimises manual alignment

4th Axis Mounting

Nextas Zero Point Plates easily mount to 4th axis rotary tables where vices and custom tombstone fixtures can be quickly hot swapped without manual realignment.

Industry Standard Compatible

The 52/96mm pull stud mounting pattern is compatible with industry standard vices and tooling allowing for easy integration with existing systems